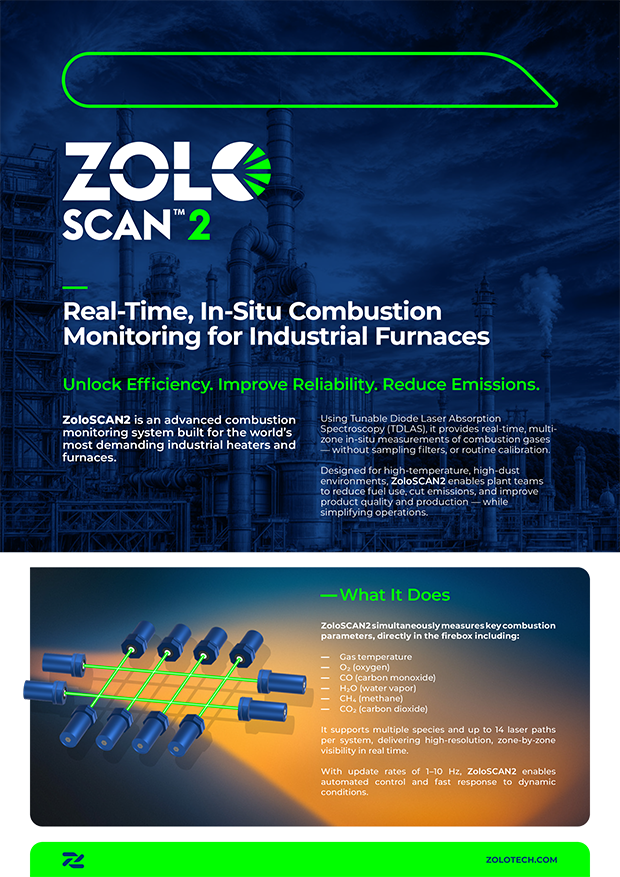

Power & Boilers

Balance combustion in real time to cut fuel costs and extend uptime.

Boilers must maintain reliability, efficiency, and emissions compliance while adapting to variable grid demand. With more solar and renewables, operators now ramp from 25% to 100% load several times a day. Zolo’s real-time, in-situ measurements of O₂, CO, H₂O, and temperature help stabilize combustion through these transitions—reducing slagging, fouling, and tube leak risks while enabling tighter control of NOx and CO formation at the source. The result is improved uptime, lower fuel intensity, and sustained compliance—all without the drift and maintenance burden of conventional oxygen probes.